All you need is an ordinary wirewound resistor, which will serve as a donor for the resistor material. The problem with the wirewounds is not the wire, its the wound. So we can use the wire for our purposes if we simply unwind it and keep it straight.

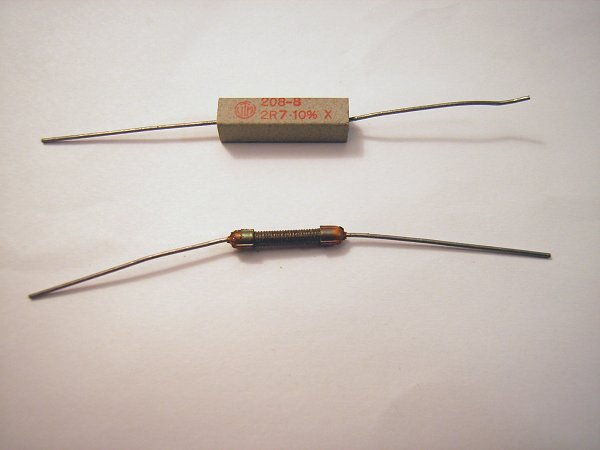

Choose a wirewound of somewhat higher value than you need for your application (see below). A good choice are concrete resistors as shown in the upper part of the image. You can easily remove the concrete by cracking them in a vice. Under the concrete, as shown in the lower part of the image, you find the wire, wich is wound on an insulating carrier.

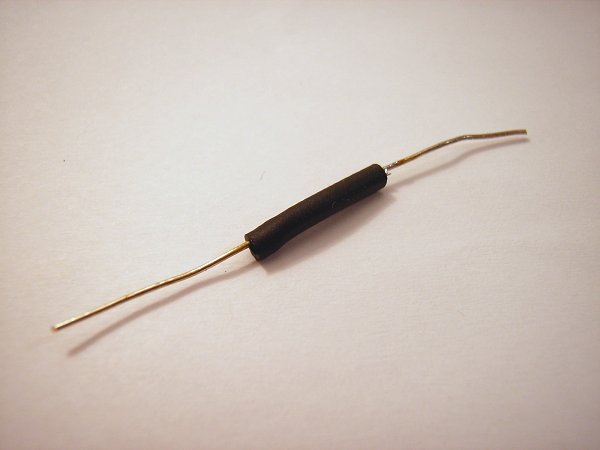

Cut off the metal caps at both ends of the resistor with pliers. Then you can unwind the wire.