|

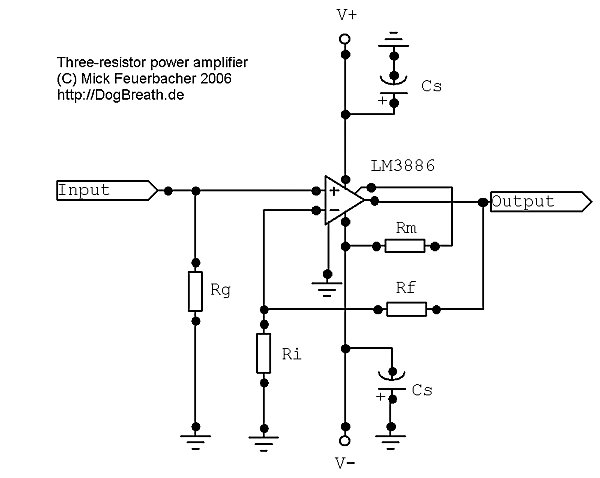

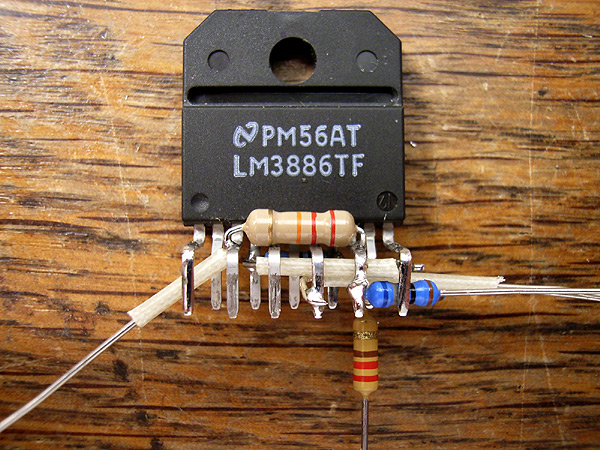

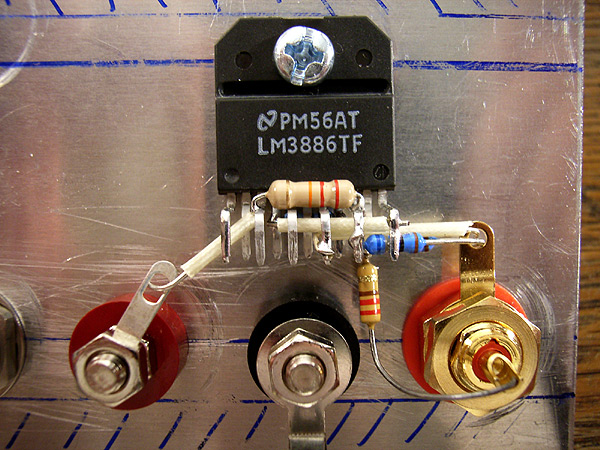

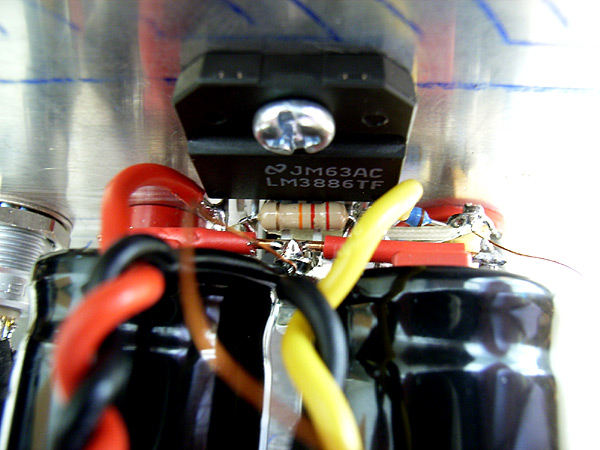

This project is a minimalistic LM3886 based power amplifier. It has only

the minimum number of parts in the signal path: Three resistors - nothing

else. These three resistors are required for the functionality of the

amp so further simplification in this sense is impossible. Referring to

the schematic below, the three resistors are Rg, which sets the input

impedance of the amp, and Rf and Ri, which set the gain. In particular

in this design the use of an input coupling cap is avoided. This greatly

improves clarity and transparency, in particular if the preceding stage

has output coupling capacitors. These would otherwise be unnecessarily

cascaded with the input capacitors, which is not good for the sound. If

you want to build this amp, be however careful if you are not sure if

the preceding stage in your system has output coupling caps. If it has

not, DC may enter the amp, which will be amplified and sent to your speakers!

Also, be careful if you have difficult to drive speakers. The amp has

no Zobel network or any other stabilizing components.

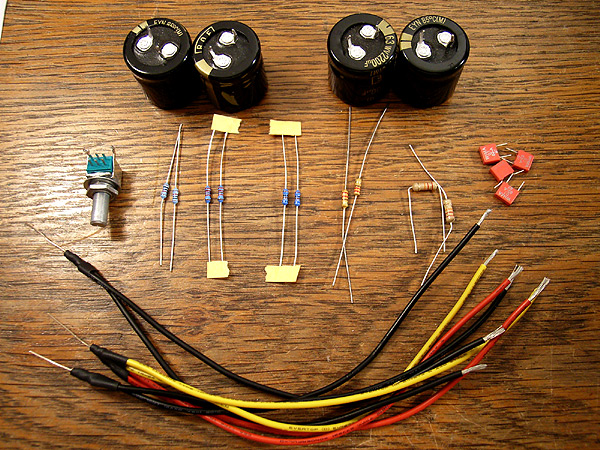

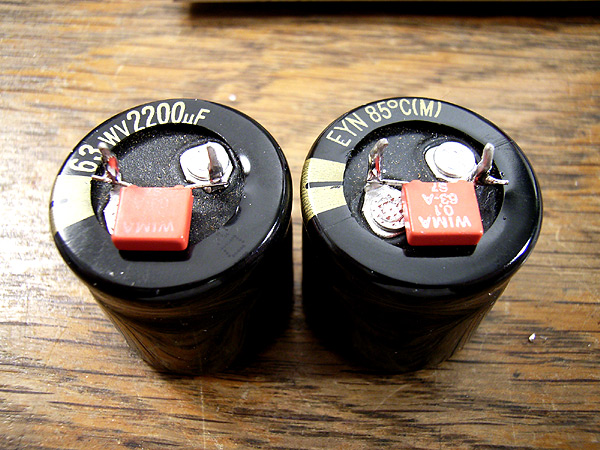

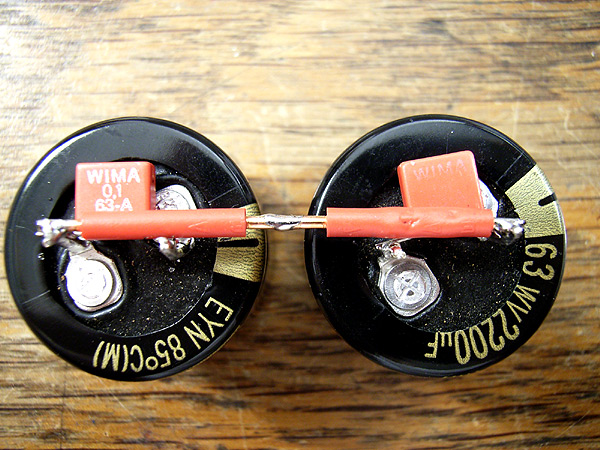

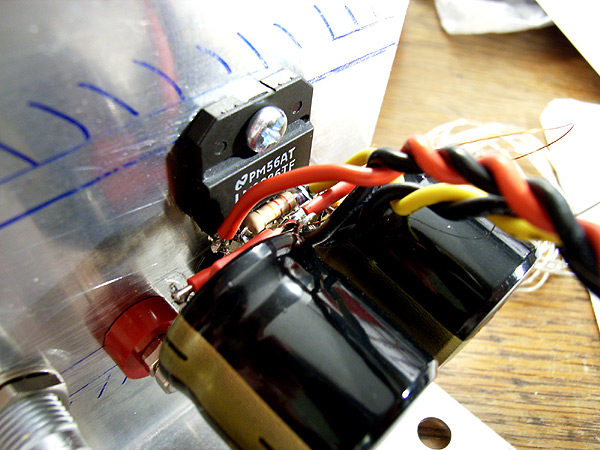

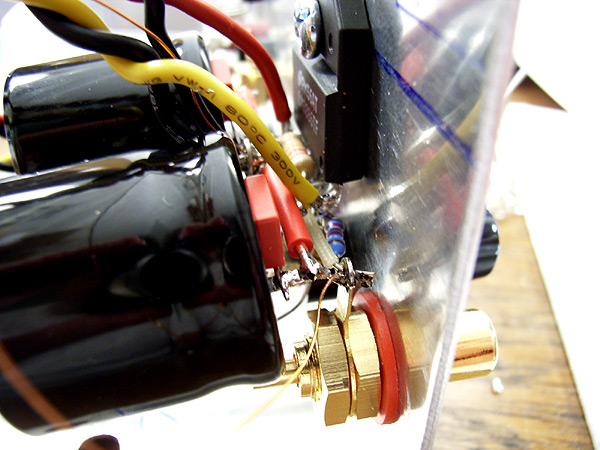

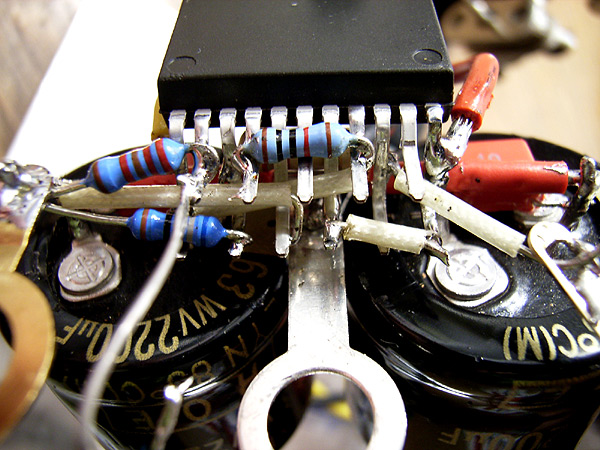

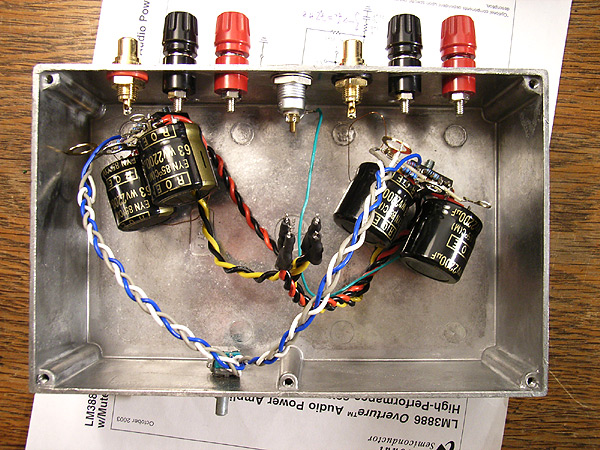

Of course finishing the amp requires additional parts, but these are

not in the signal path. The LM3886 has a muting function which requires

the addition of a resistor Rm to V-. Also power supply bypassing is required,

which here was done with a 2200 uF electrolytic parallelled with a 100

nF film capacitor.

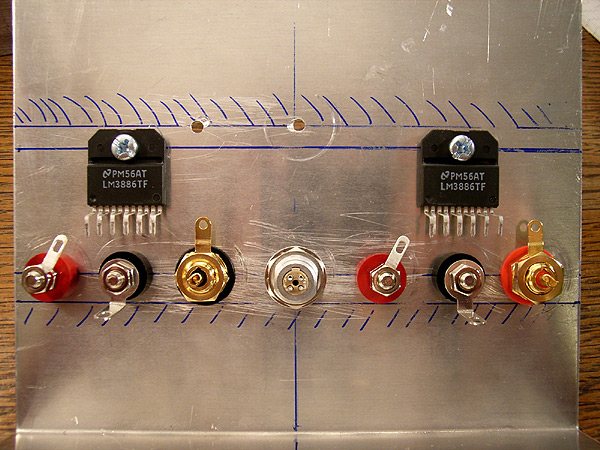

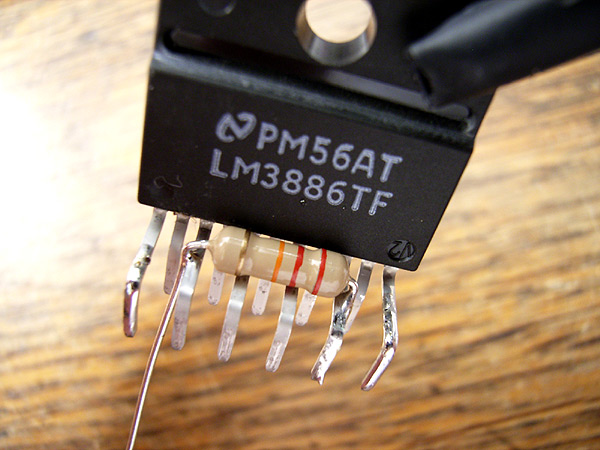

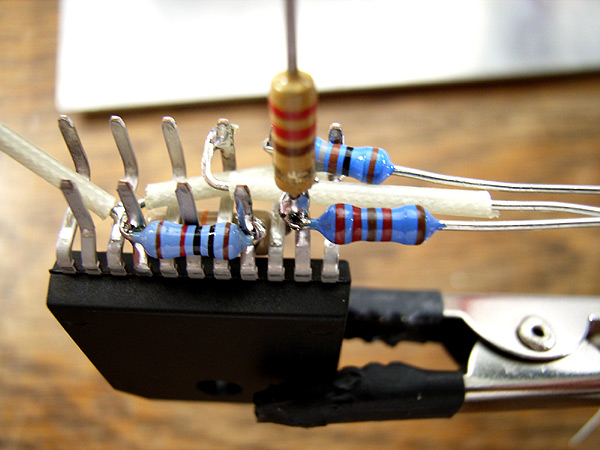

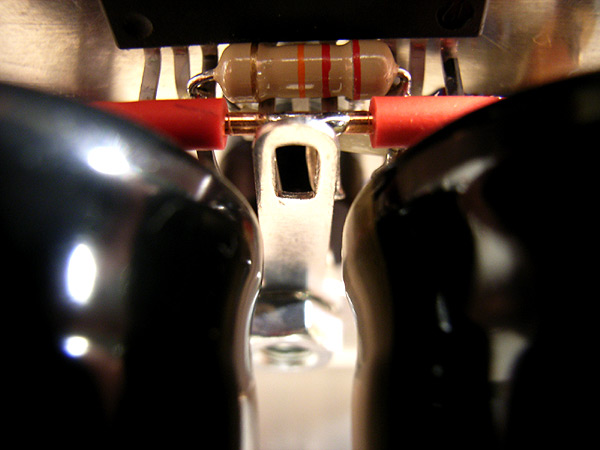

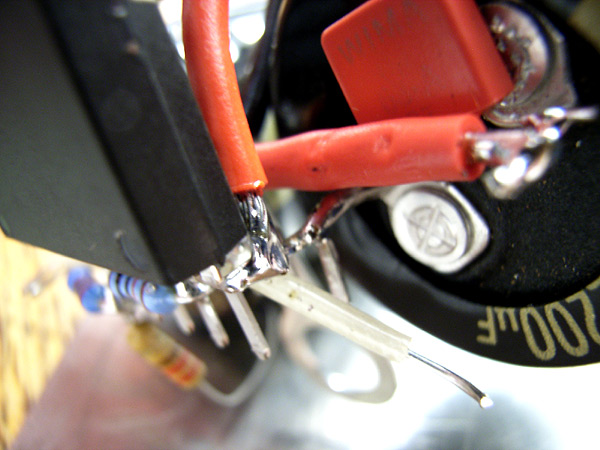

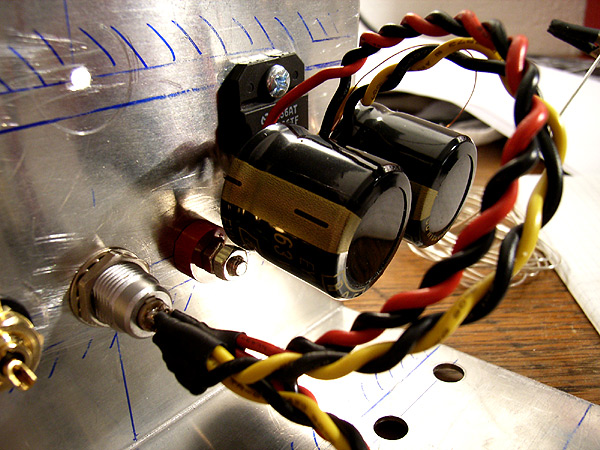

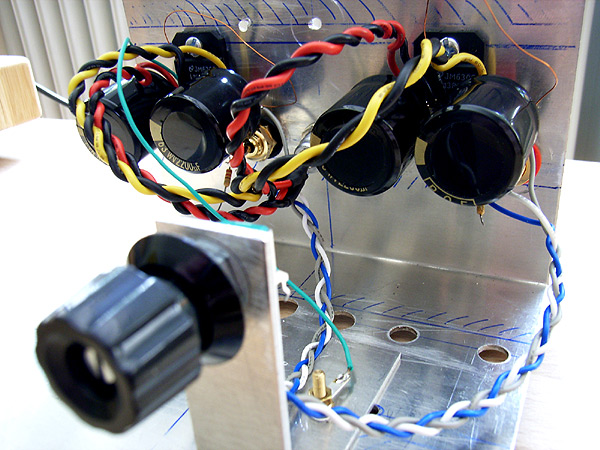

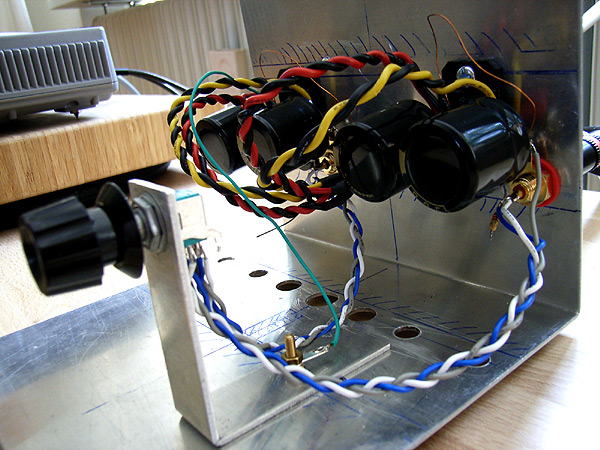

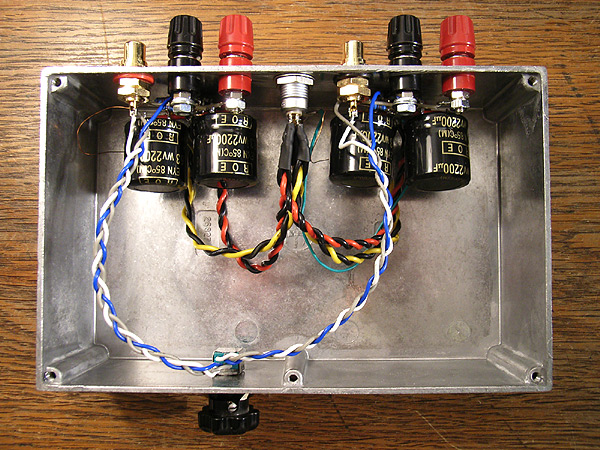

The amp is built point-to-point, i.e. no PCB or matrix board was used.

The geometry was chosen according to the following criteria. i) I wanted

to have it extremely compact and ii) I minimized the area of any current

loops, which lead to unwanted incuded voltages in the circuit.

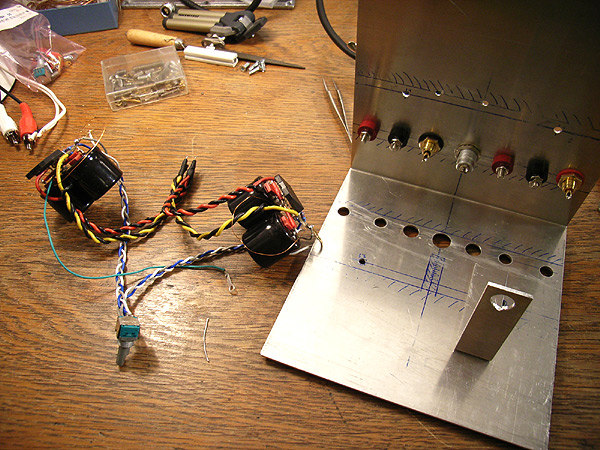

In the following you find an illustrated description of the build process

of my amp. It is rather detailed and step-by-step, which may be helpful

for beginners. You are invited to use it as a guide for building your

own amp - if you do so, I would be grateful for your feedback..

|