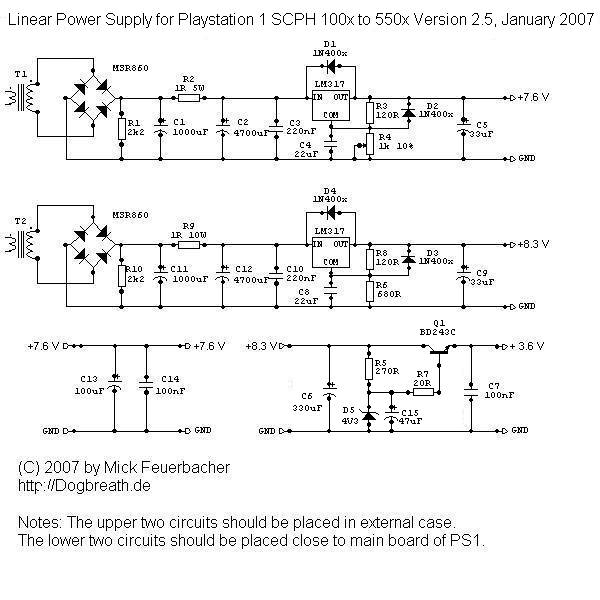

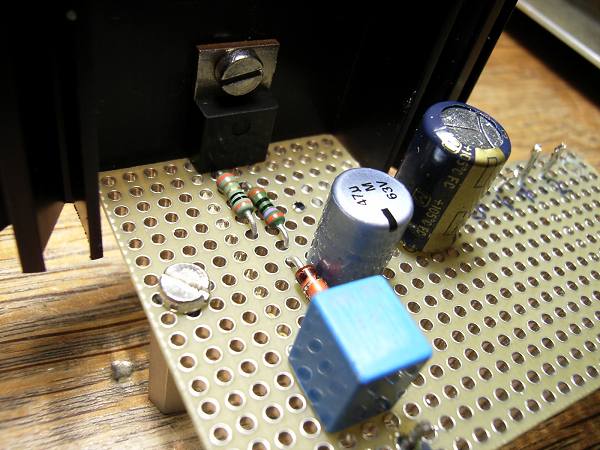

The schematic of the new PSU. I decided to build a single regulation

for the 7.6 V line and double regulation for the 3.6 V line. The first

regulation steps are done via LM317 regulators. In order to keep the 7.6

V line adjustable, a 1k trimmer is used. It has to be set to about 610R

for an output voltage of 7.6 V.

The 8.3 V line does not have a trimmer because it is further regulated

anyway. Make sure that the serial regulators R2 and R9, forming low-pass

filters with C2 and C12, respectively, are rated high enough. 5 or 10

W types should be used, wirewounds are ok here.

The second regulation step is done via a discrete Zener regulator. A regular 4.3 V Zener diode will, with the Ube voltage drop at Q1, lead to the correct output voltage (the voltage drop over the base-stoper R7 is negligible), You may be forced to try several Zener diodes before you find one which gives the correct voltage drop - they are usually not very precise.

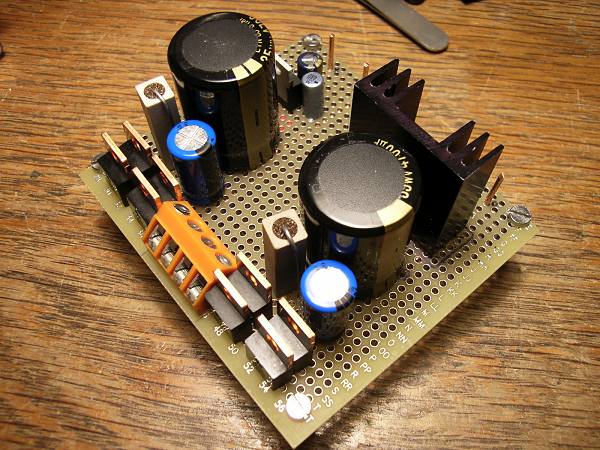

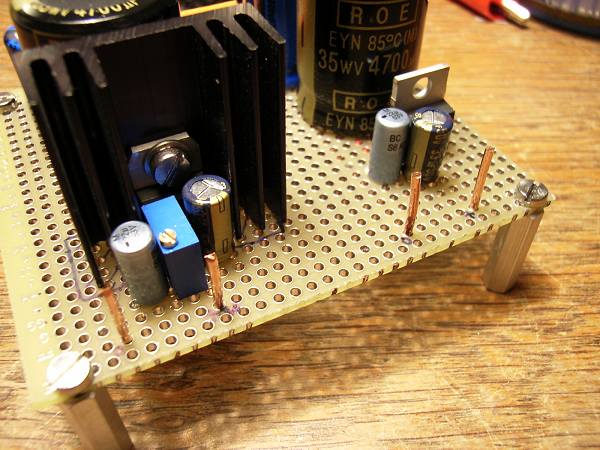

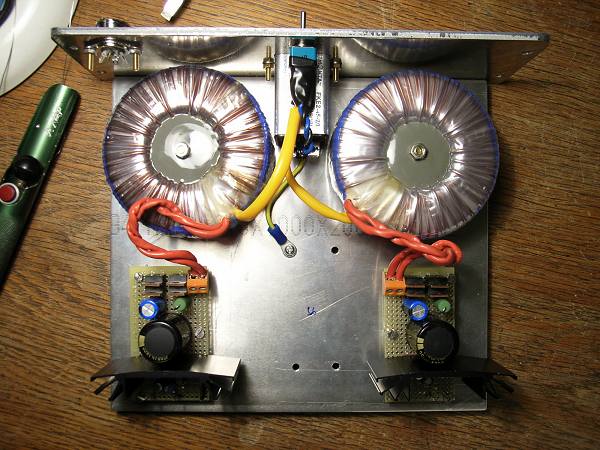

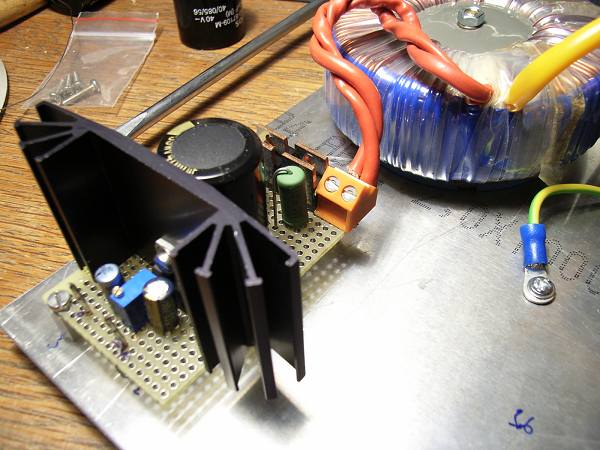

The two lines providing the first regulation step (upper two circuits)

should be placed in a separate case (because of the heat created in the

LMs and the serial resistors, and because the space in the PS1 is too

much limited anyway. The second regulation step, however, should take

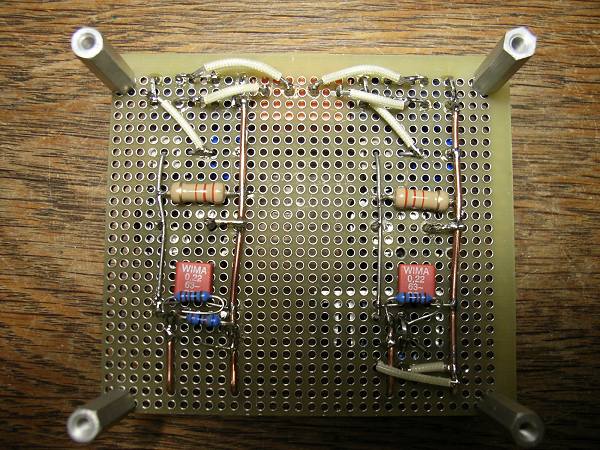

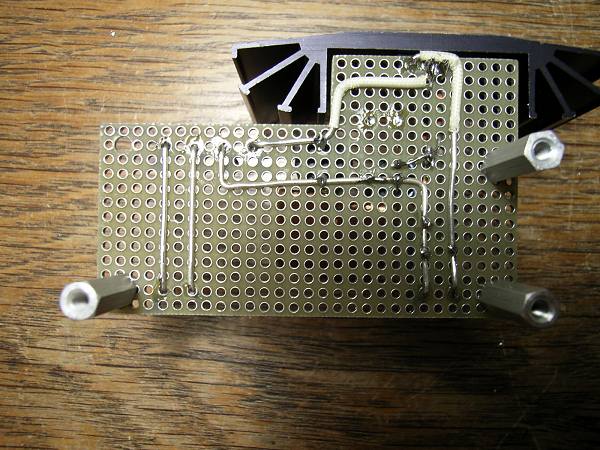

place as close as possible to the main board of the PS1. Build the lower

to circuits on a separate board and put them in the free space in the

PS1 case, where the stock SMPS was placed. This ensures that the supply

is as clean as possible, and noise caught by the umbilical is filtered

out at the board.

Accordingly, the lower left supply is sort of a "reservoir stage"

for the 7.6 V supply line. C12 and C6 at the inputs of these two circuits

form another low-pass filter with the resistance of the umbilical ;-)