|

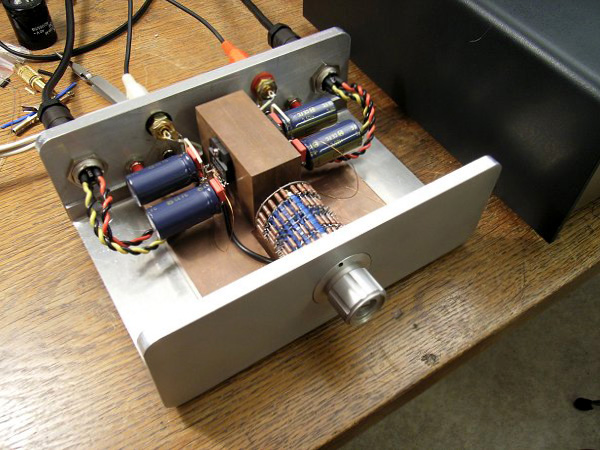

I decided to build the amp into a commercial case from Conrad. It turned

out that the build quality of the case was very low. The front and back

plates were made of awfully thin aluminum and the screw connections were

worn right from the beginning.

Therefore I only used the upper and lower steel covers and made the complete

rest by myself, using massive aluminium. The front and back plates are

8 mm thick, the bottom plate is 4 mm.

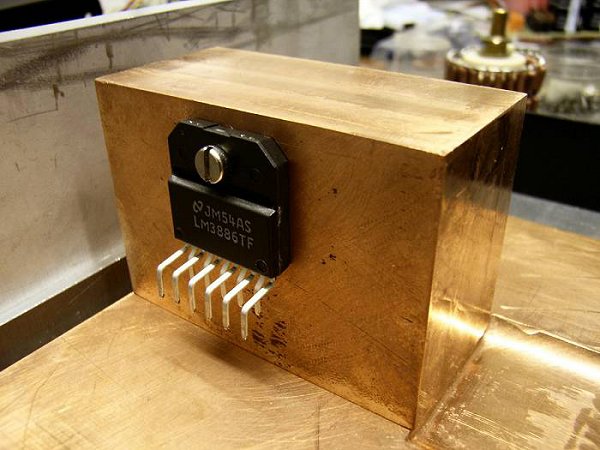

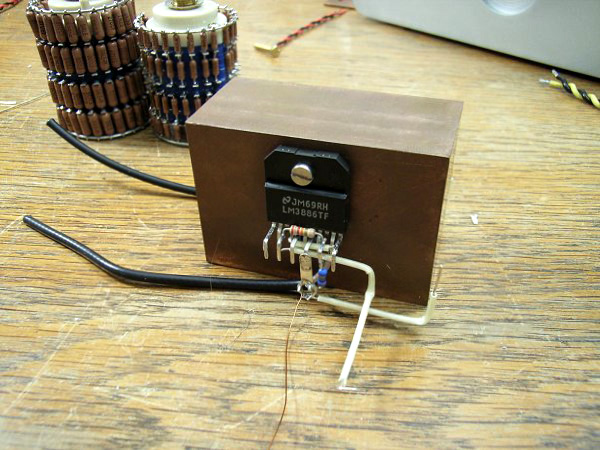

On the picture you also see some of the parts to be used. The Cs capacitors

are well approved Panasonic FC types, the pot is a stepped attenuator

as sold by http://diyfidelity.com.au/.

|